December ’24 Status: I believe this issue is resolved per replacement of fuel injectors.

These notes are modified from an old forum post related to a P0302 check engine light (CEL), subsequent troubleshooting, and eventual replacement of fuel injectors.

In October 2024 I had a P0302 code pop up on my 97 Jeep Wrangler. I did a quick visual inspection and noticed there were exposed wires on the cylinder 2 fuel injector (the others looked OK as far as I could tell).

If there was direct contact between the two wires for the fuel injector, then I assume this would cause a complete malfunction of the fuel injector and would be related to the P0302 warning. Even with the insulation damaged/missing between the wires at the harness, it’s my intuition that there could be occasional arching which would prevent the fuel injector from working properly continuously and trigger P0302.

With the cylinder 2 fuel injector wires looking shot, I’m sure there are other wires not far behind. The shot wires could also be completely unrelated to the P0302 code.

The distributor, sparkplugs, and spark plug wires were replaced in September 2024. I had this done in a shop while they were also doing some emissions related work.

With the wires being so brittle, repairing is difficult. I applied a temporary fix with some liquid electric tape first. Eventually, I will look into where I can buy new wires, harnesses, etc.

Later, I pulled the #2 spark plug (just looking at the easiest things to inspect next). The plug was a little gunked up (not terrible) and the gap was a little short. I cleaned it, adjusted the gap, reinstalled and checked that the plug wires were seated OK.

Then, I did this I did…

- I checked the fuel injector harness with a noid light and it was flashing, so it looks like the fuel injector was getting power as it should.

- I pulled the #2 spark plug again and checked its resistance. It was somewhere around 5.2K ohms, which I think is OK (I also verified that there was no current/continuity between the terminal and ground electrode). I measured the spark plug at ~17″ and 6.7K ohms, which I think is OK too.

- I used an inline spark tester to verify electricity was reaching the spark plug.

- I ran the engine and recorded audio with screwdriver held up against my phone mic on fuel injectors one through three for comparison. All had ticking/actuating sound, but injector #1 and #3 sounded stronger than injector #2.

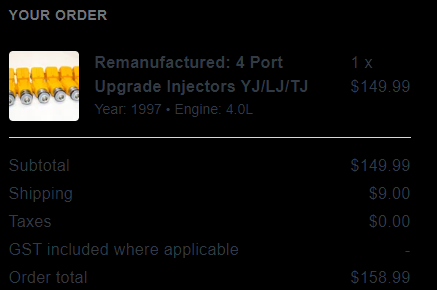

This was all leaning towards a bad fuel injector (#2). So, I decided to replace all six fuel injectors. I was tempted to try cleaning the ones I had, but thought that it was probably best to just go ahead and replace them if I was going to the trouble to remove them. Some folks on the original forum post gave me some suggestions on where to purchase, and I ended up purchasing refurbished 4-hole injectors from K Suspension.

Here’s what the old ones looked like…

I replaced them myself and drove around a little bit. The engine felt and sounded a lot better. I think that disconnecting the battery cleared the P0302 code, but as of December 2024 the code never came back on (after several wheeling trips).

Here’s what they look like on the engine…

You can see in the picture above that there are additional wire issues that need to be addressed. The degradation of wire insulation is throughout the vehicle and I will address all of this over time.

I was surprised that the performed so much better than it did before replacing the injectors. I’ve never owned a Jeep before, so I wasn’t really sure how it “should” feel on those long, steep paved climbs. Before, it felt pretty lethargic. But that was in comparison to the newer vehicles I drive (a ’22 Ram 1500 with a V8 and a ’15 Mazda CX-5). I had also read a lot about people complaining about their TJ’s performance on the road, and I knew that the 35″ tires would effect performance as well. I bought this Jeep as a starting point as a rock crawling rig based on a lot of research, but no personal experience with the TJ platform. Now, with the new fuel injectors, it does great driving up the steep paved hills around my house. This isn’t an offroad “test”, but it gives me a good idea of overall performance – including a better overall idea of how the vehicle “feels”, sounds, smells, etc. (yes, “smell” – especially after work on emissions system, fuel injection system, etc.). As an example of testing how the vehicle “feels”, I’ve used this route with and without the sway bar links connected, several different wheel/tire combinations, etc.

This local hilly drive is a good baseline for me since I have driven this route hundreds of times in other vehicles (including pulling trailers). You get a “feel” for how your vehicles could/should drive using familiar roads.

It was interesting experience replacing the fuel injectors, which is not something I’ve done before. I watched some videos on YouTube beforehand to get an idea off the procedure. The biggest difference between what I saw in those videos versus my particular Jeep was how my aftermarket air intake system interfered with pulling off the fuel rail. But I suppose differences are to be expected on vehicles this age with a lot of aftermarket parts and additional work done on them. Actually pulling the fuel injectors required some force and patience. I ended up climbing on top of the engine bay in order to get a better angle to pull the fuel rail, being very mindful to not break anything with a clumsy foot or knee. It probably looked a little ridiculous, but I found it a lot easier than trying to lean over into the engine bay on this lifted Jeep.