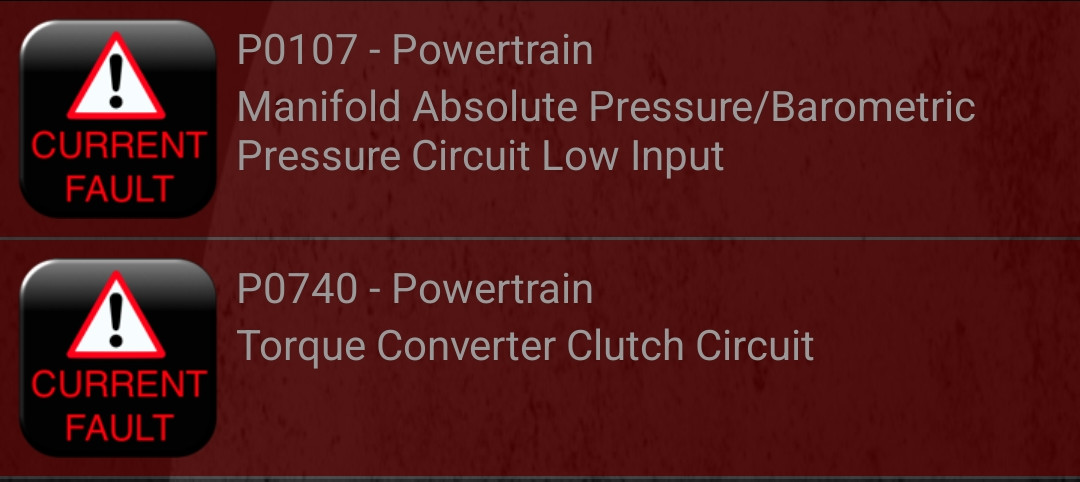

I’ve had an intermittent MIL with P0740 on my 97 Wrangler since I bought it used in September 2024.

Also see: 97 Wrangler P0107 (potentially related to root cause oof “bad” PCM)

This is just laying out my plan and notes for the next time I mess with this (I’ve already changed/checked transmission fluid and done a few other things, which I might add to my notes later).

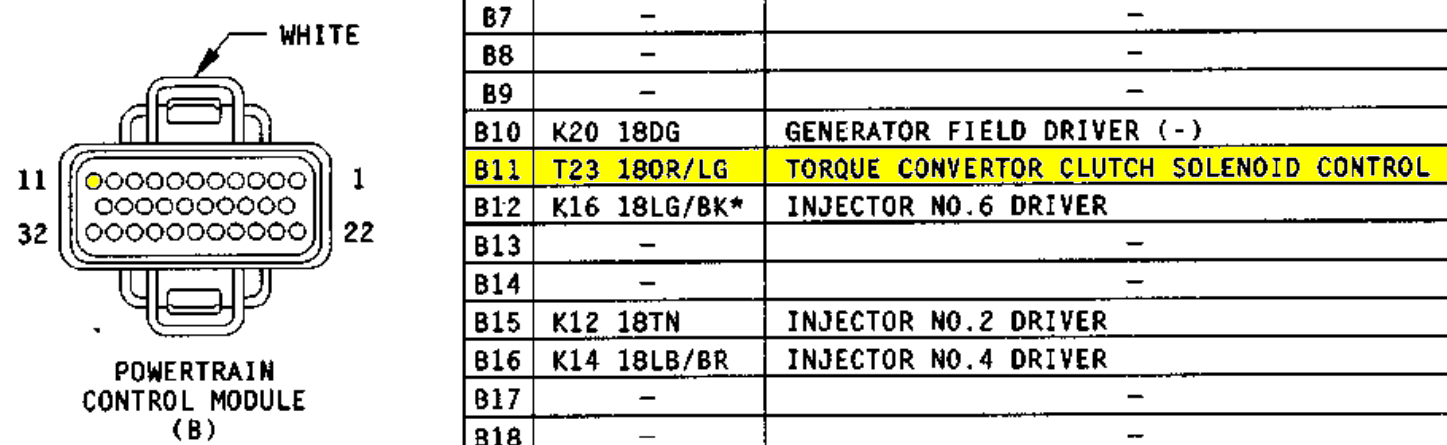

I suspect the issue to be with the PCM and/or wiring from the PCM to the transmission. Page 599 of the 1997 Jeep Wrangler Service Manual PD (referenced as “8W – 80 – 19”) shows that the connector pin B11 output at the PCM (B) is associated with circuit “T23 18)R/LG” with function “torque converter clutch solenoid control” (i.e., pin B11 should have continuity at the TCC solenoid).

Page 473 indicates that the other TCC solenoid wire (18RD/LG) is connected to a 10 amp fuse (fuse 11).

So, the wire should be at 12 volts when the Jeep’s key is in the start or run position. Between the ignition and the battery, there is another fuse, but I’ll focus on PCM to TCC continuity, and fuse 11 state (12V, not blown) and continuity next.

Plan

- Inspect fuse 11 (make sure it isn’t blown)

- Check 12V at TCC from fuse 11

- Check continuity between PCM/B11 pin and TCC

- Verify there is not continuity between PCM/TCC wire, ground, and other wires in harness

- Check/clean all exposed connectors and ensure they are well secured when done

- Check ATF fluid after driving (ATF warm), engine running, and in neutral (verify this is correct procedure for 32RH transmission)

ATF check procedure

32RH Automatic transmission fluid level check procedure (copied/modified from page 1,000 in 97 Wrangler manual). ATF+3 was originally specified by the manual, but ATF+4 is now recommended.

- (1) Transmission fluid must be at normal operating temperature for accurate fluid level check. Drive vehicle if necessary to bring fluid temperature up to normal hot operating temperature of 82°C (180°F).

- (2) Position vehicle on level surface.

- (3) Start and run engine at curb idle speed.

- (4) Apply parking brakes.

- (5) Shift transmission momentarily into all gear ranges. Then shift transmission back to Neutral.

- (6) Clean top of filler tube and dipstick to keep dirt from entering tube.

- (7) Remove dipstick (Fig. 13) and check fluid level as follows:

- (a) Correct acceptable level is in crosshatch area.

- (b) Correct maximum level is to MAX arrow mark.

- (c) Incorrect level is at or below MIN line.

- (d) If fluid is low, add only enough Mopart ATF Plus 3 [or 4, per later Jeep guidance] to restore correct level. Do not overfill.

CAUTION: Do not overfill the transmission. Overfilling may cause leakage out the pump vent which can be mistaken for a pump seal leak. Overfilling will also cause fluid aeration and foaming as the excess fluid is picked up and churned by the gear train. This will significantly reduce fluid life.

Other thoughts

Assuming the above plan doesn’t yield an obvious root cause and/or the MIL/P0740 code comes up again, I can look into the normal operating conditions and timing characteristics of this circuit and use probes/multimeter to help determine if the PCM and TCC are operating as expected. I’m hoping it’s a simpler wiring issue of course! The issue seems somewhat deterministic (MIL/P0740 has come up several times now) but the long term timing and potential intermittent could be frustrating. I’ll just look at this a a long term diagnosing effort – one small step at a time.

Checked transmission fluid today and it was low (less than a quart). No obvious signs of leaks. Filled to max line.

Checked fuse 11 today while I was doing other things and it looks fine

Just noting that I drove around a little today and the code hasn’t come back (or any other code). This was also after a wheeling trip on the 22nd. Knock on wood! (But I do suspect we’ll see this code pop up again eventually). I have a long list of things I’ll eventually work on, but the only things related to this code (besides the outstanding diagnostic “to dos” in this post) are replacing old wires and routine maintenance (I’ll probably keep a closer eye on transmission fluid levels for a while).

It’s been a few months now and I haven’t seen the code come up. We’re also getting into warmer weather, which might effect things.